We put our heart and soul into each and

every one of our Japanese sweets to convey warmth.

-

Yano Foods was founded in 1948

and has been making sweets

for nearly 70 years.Everything is

for your “Delicious”Food has to taste good.

These are the words of our founder.

In order for our customers to say “delicious,” we will continue to make efforts every day.

We will continue to research raw materials, manufacturing methods,

formulas, etc., without settling for the status quo. -

Taste of grandma's cooking

Taste of grandma’s cooking

The Japanese sweets we make are not those of a high-class store.

but rather as home-style cooking.

We aim for the warm, nostalgic taste of the ohagi and kashiwa-mochi

that our grandmothers used to make in our hometowns.

We aim for that kind of nostalgic and warm taste.

Manufactured Products

Lineup

-

Ohagi

The dough prepared by steaming glutinous rice produced in Hiroshima Prefecture has a more mochi-mochi texture than dough made from cooked rice, and the taste of the rice can be felt more clearly. There are two types of mochi: one wrapped in our signature homemade sweet bean paste, and the other with the sweet bean paste wrapped in the dough and covered with soybean flour.

- Standard

- 18g / 30g / 50g / 90g / 110g

- Storage

temperature - -Under 18 degrees

- Best-by date

- 6 months to 400 days (frozen) After thawing: 2 days

- How to thaw

-

(In the case of one 50g Ohagi)

Heated in a 600w microwave oven for 20 seconds, then at room temperature for 10 minutes.

Re-freezing is not possible

-

Handmade Ohagi

This o-hagi is hand-wrapped with special handmade o-hagi grain red bean paste, which is made with a lower sugar content and lower sweetness than regular grain red bean paste, so as not to damage the ingredients. The dough is not sweetened, but rather steamed glutinous rice mixed with salted water and then steamed twice.

Because it is wrapped by hand, the grains of rice are less likely to be crushed.

Because the sugar content is low, the dough has an extremely short shelf life and cannot be frozen, so it is prepared every morning and shipped every day.- Standard

- 100g

- Storage

temperature - 20 degrees Celsius or less

- Best-by date

- 2 days (not to be kept in cold, at room temperature)

-

Sakuramochi

It is made by processing raw glutinous rice by steaming, without using domyoji flour. Glutinous rice soaked in water overnight is gently steamed with moist steam and combined with boiling water in which sugar and salt are dissolved.

Natural coloring is used to create a gentle coloring.

The bean paste is made from Hokkaido azuki beans. Beet sugar is used to give it a refreshing sweetness, and coarse salt is used to season it.- Standard

- 18g / 25g / 35g / 50g / 90g

- Storage

temperature - -Under 18 degrees

- Best-by date

- 360-400 days (frozen)

- How to thaw

-

(For one 50g Sakuramochi)

Heated in a 600w microwave oven for 20 seconds, then at room temperature for 10 minutes.

Cannot be refrozen.

-

Kashiwamochi

The dough for Kashiwa Mochi and dumplings is prepared in a steaming machine. The steam is heated and kneaded by a craftsman who adjusts the amount of steam by watching how the steam escapes. The dough is heated a little longer to allow for firm alpha-formation and to make it soft and stretchy. The filling is homemade bean paste.

- Standard

- 25g / 50g / 70g / 90g

- Storage

temperature - -Under 18 degrees

- Best-by date

- 360-400 days (frozen)

- How to thaw

-

(For one 50g Kashiwamochi)

Heated in a 600w microwave oven for 20 seconds, then at room temperature for 10 minutes.

Do not refreeze.

-

Mame Daifuku

The steaming and kneading machine is used to gently and thoroughly aerate the flour, resulting in very soft and stretchy Daifuku. Salt is added.

The black beans are steamed slowly with soft steam. The beans are then steamed slowly with soft steam, and while sprinkling water during the steaming process, they are steamed to the right degree of firmness. No added sugar is used, allowing the flavor of the black beans themselves to come alive.

The taste and texture of the black beans are enhanced by the soft dough.

The homemade bean paste made from Hokkaido azuki beans is not too sweet, so it does not interfere with the taste of the black beans. Please enjoy the trinity of flavors.- Standard

- 90g

- Storage

temperature - -Under 18 degrees

- Best-by date

- 400 days (frozen)

- How to thaw

-

(For one 90g piece of Mame Daifuku)

Heated in a 600w microwave oven for 30 seconds, then at room temperature for 10 minutes.

Cannot be refrozen.

-

Warabimochi

We adjust the type and amount of starch and carbohydrates to create products with texture, softness, and sweetness close to the user's wishes.

We can jointly develop original warabimochi by changing soybean flour, blending brown sugar, green tea, yuzu, etc. (Minimum lot size: 2 tons)

Our products are used in restaurants, conveyor-belt sushi restaurants, cafes, bento boxes, and many other places. It is also used as a topping for parfaits and other dishes.

Because they are coated with soybean flour and cut, you can take out and defrost only the necessary number of grains even if they are frozen.- Standard

- 545g

- Storage

temperature - -Under 18 degrees

- Best-by date

- 360 days (frozen)

- How to thaw

-

(For 7 pieces of Warabimochi)

Heated in a 600w microwave oven for 20 seconds

Do not refreeze

-

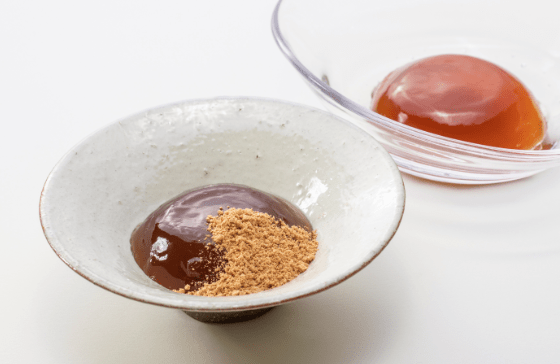

Brown Sugar Warabimochi

These strawbutter cakes are so soft and stretchy in texture that they cannot be cut.

Please enjoy it with chopsticks.

The brown sugar from Hateruma Island is used to minimize the amount of sugar in the product, allowing you to enjoy the robust flavor of the brown sugar while keeping the sweetness low.

Several types of starch, including honwarabi flour, are blended to create a texture that is elastic, yet smooth and easy on the palate.

It is even more delicious when sprinkled with sugar-yellow powder.- Standard

- 70g×3

- Storage temperature

- -Under 18 degrees

- Best-by date

- 360 days (frozen)

- How to thaw

-

2 hours for natural thawing.

Cannot be refrozen.

-

Mushimanju

Because it is frozen, it does not require extra sugar to make it last longer, and as a steamed bun, it has less sweetness and is more moist when freshly made.

Usukawa manju:

A thin dough made from Japanese yam with a moist texture is used to fill the steamed bun with a large amount of Hokkaido-azuki bean paste.

Rikyu Manju:

Brown sugar flavored steamed buns with brown sugar kneaded into the dough. It is filled with red bean paste made from Hokkaido azuki beans.

Sake manju:

A dough rich in sakekasu (sake lees) is used to wrap the red bean paste made from Hokkaido azuki beans. The flavor of sake can be felt in this sake bun.- Standard

- 30g~35g

- Storage

temperature - -Under 18 degrees

- Best-by date

- 360 days (frozen)

- How to thaw

-

(For one 35g Usukawa manju)

Heated in a 600w microwave oven for 20 seconds, then at room temperature for 10 minutes.

Cannot be refrozen.

-

Frozen Mochi /

Frozen AnmochiIt is made using only new glutinous rice harvested that year and produced in Akitakada, Hiroshima Prefecture (at the end of the year).

The rice is gently steamed with moist steam, pounded with a pestle, and then quickly frozen after forming.

Therefore, they are always delivered in a state close to freshly made.

Anmochi are homemade red bean paste made from Hokkaido azuki beans and wrapped in a pounded rice cake.- Standard

- 45g~55g

- Storage

temperature - -Under 18 degrees

- Best-by date

- 360 days (frozen)

- How to thaw

-

(In the case of one 55g frozen anmochi)

Heat in a 600w microwave oven for 25 seconds, then heat in a 1000w toaster oven for 3 minutes.

Cannot be refrozen.

Tamayamochi

Commitment

Production

method

Making Anko

- ・The cooked beans are slowly and thoroughly astringent to reduce the taste of impurities.

- ・Cooking is done in a special pot with less “kneading”. The rice is cooked gently so as not to damage the ingredients.

- ・Hokkaido beet sugar is used for a sharp sweetness. Coarse salt is added at the end to taste.

Preparation

- ・Glutinous rice and black beans are heated by “steaming. Humid steam gently envelops the rice and brings out the flavor and texture of the ingredients.

- ・All rice cakes and dumplings are pounded with a pestle. This brings out the original firmness and stickiness of the rice cakes.

Combination

- ・We try to blend the ingredients in a way that brings out the best of their flavors. We do not add extra sugar to make the product last longer, but rather blend it to a sugar content of 40-52 degrees.

- ・Sugar is mainly beet granulated sugar, and trehalose and other ingredients are utilized to create a light taste. Salt is used to taste and enhance the sweetness.

- ・No preservatives, shelf-life enhancers, or synthetic colors are used in Tamaya Mochi frozen Japanese sweets.

- ・Tamayamochi's Ohagi, Sakuramochi, etc. are made mainly from domestic ingredients such as sugar, azuki beans, and glutinous rice. We do not add any unnecessary ingredients and value the original taste of the ingredients.

Raw

materials

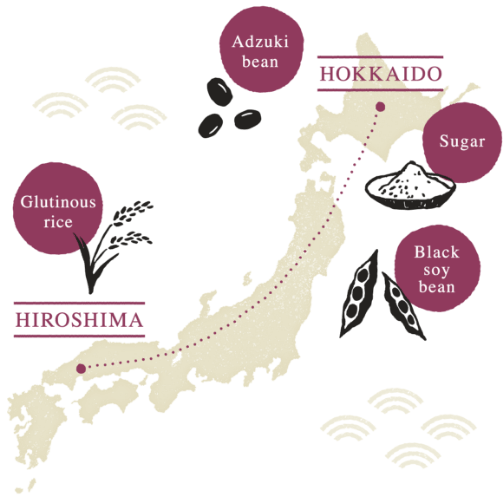

Glutinous rice

Glutinous rice grown in Akitakada City, Hiroshima Prefecture, is used. It is the area in Hiroshima where glutinous rice is grown the most. The city is located near the watershed, and water from the Chugoku Mountains flows into its fields, nurturing very tasty rice. At the end of the year, only new rice is used to make mochi (rice cakes).

Adzuki bean

We use azuki beans grown in Tokachi, Hokkaido. Only Erimo red beans are used for handmade o-hagi and other products. Because they are susceptible to disease and difficult to cultivate, their cultivation is decreasing year by year, making it difficult to secure them, but they are azuki beans with excellent flavor, taste, and color when made into bean jam.

Sugar

Beet granulated sugar is made from sugar beets produced in Hokkaido. Compared to sugarcane

granulated sugar, beet sugar

has a more consistent sweetness, giving the bean paste a lighter taste.

In addition, brownstrap molasses made from 100% brown sugar from Hateruma Island, Okinawa,

is used to produce

warabi-mochi and other products. We actively use domestically produced sugar to make

Japanese sweets.

Black soy bean

The black soybeans used for Kuromame Daifuku are grown in Hokkaido.

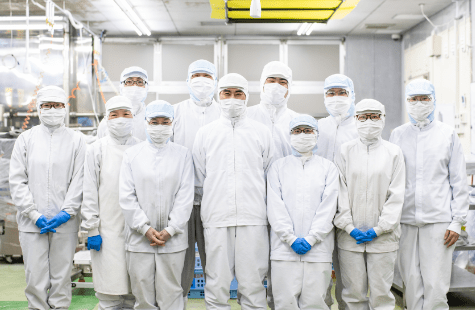

Safe and

Secure

Sanitation

FSSC22000 Third-party

certified

Obtained on July 24, 2023

Certification body: LRQA

PCQI Certification

Acquired 2 persons

Creating products that are gentle to the human body

We do not use preservatives, shelf-life enhancers, synthetic colors, or chemical seasonings

in our frozen rice cakes and

wagashi.

We try our best to make products using only the finest ingredients and as little additives

as possible.

(Handmade o-hagi, which are made and shipped daily, use a shelf-life enhancer because their

sugar content is extremely

low and they do not last long.)

Frozen

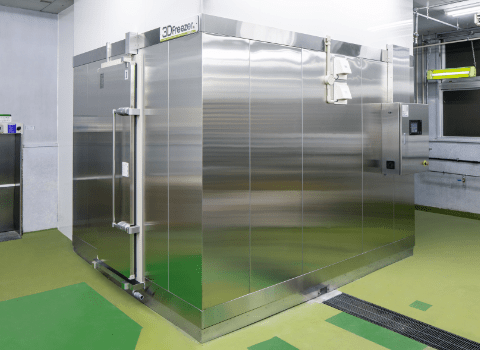

3D-Freezer

Introduced the “3D-Freezer,” a quick-freezing chamber, in February 2023.

This is a revolutionary freezer that can freeze products in a short time while preventing

them from drying out. This

will enable us to produce Japanese confectioneries that are fresher, less damaged when

frozen, and in a state close to

freshly made.

Joint Development and

Private Brand Product Development

Yano Foods is able to develop formulas and manufacturing methods

that meet our customers' requirements based on our many years of experience.

We have also received many requests for private brand products.

We are happy to make proposals in response to your requests and problems.

●Forexample.

-

Restaurant chain:

Soft and chewy texture of strawbaked warabimochi.

-

Lunch box

manufacturer:Japanese sweets with seasonal ingredients for chopstick rest.

-

Food service

companies:Elderly facility residents are pleased with Steamed buns with combined calories.

-

Mail order company:

Incorporating cereals, etc. Ohagi, Daifukumochi

-

Rest stop:

Dumplings made with local rice to showcase the area of production.

-

Export firm:

For possible sale in the U.S. and Europe Wagashi with adjusted ingredients.

In addition to the above, we are happy to meet with our customers and develop products in

collaboration with them.

We look forward to working with you in the development of your Japanese menu.

- *Lots and lead times will vary depending on the raw materials used, changes in formulas, and packaging materials.

- *There are some ingredients such as allergens that we cannot handle.

Sales destination

-

Frozen sales

We sell frozen products for cooperative purchases.

Although we mainly sell consumer-oriented products, we also sell large-volume packs for commercial use. -

Restaurants

and

other commercial useRestaurant chains use our strawbutter as a topping or as an item on their menu. Each chain restaurant uses a different formula, and each restaurant uses a different taste, texture, and flavor to differentiate their products from the others.

Bento lunch box manufacturers offer bite-sized Japanese sweets as a side dish. Seasonal products such as sakura mochi(cherry blossom cakes) and standard products such as ohagi (rice cakes) are used to add color to bento boxes. Even though they are for business use, we use Hokkaido-shima azuki beans and domestic glutinous rice, and provide high quality products using the same manufacturing process as our regular products.

A food service company for the elderly uses our steamed buns as a snack for the residents of their facilities. -

Mass retailer

We deliver to mass retailers in two ways: frozen and daily delivery.

Since the shelf life at room temperature is 2 to 3 days, daily delivery products are shipped daily and delivered to each store the next morning.

We offer products suitable for both the side dish and bread sections. -

Overseas

Demand for frozen wagashi is increasing among overseas restaurants and mass merchandisers.

Currently, our products are exported to the United States, China, Taiwan, Hong Kong, Thailand, Singapore, and the EU. We will continue to cultivate overseas users and deliver domestically produced wagashi to the world.

About Us

Corporate Philosophy

Everything is

for your “Delicious”

We strive to make Japanese sweets under the slogan, for the sake of our customers' one word,

“delicious”.

Most people share a common moment of happiness when they eat delicious food.

Our mission is to provide our customers with that moment of happiness through our “Japanese

sweets”.

President

Yoshitada Tamamoto

Company Profile

| President | Yoshitada Tamamoto |

|---|---|

| Location |

Head Office: Yanonishi 1-40-20, Aki-ku, Hiroshima-shi, Hiroshima, 736-0085 Yano Foods Co., Ltd. Second Factory: Yanohigashi 5-10-23, Aki-ku, Hiroshima-shi, Hiroshima, 736-0083 |

| Capital | 15 million yen |

| Sales | 700 million yen in 2023 |

| Number of employees | 14 employees, 75 part-timers |

| Description of Business |

(1) Manufacture and wholesale of fresh rice cakes, Japanese sweets, and okowa (2) Manufacture of frozen Japanese confectionery |

| Main Products |

Ohagi, Sakura Mochi, Kashiwa Mochi, Daifuku, Manju, Sekihan, Okowa, Mochi, Warabimochi, etc. |

History

| June 11, 1948 | Founded as a food distributor. Later started manufacturing and wholesaling popsicles and rice cakes. |

|---|---|

| June 11, 1964 | Established Yano Foods Co., Ltd |

| March 1977 | Capital is increased to 10 million yen and the company specializes in the production of rice cakes. |

| December 18, 1991 | The head office and factory were moved to the current location, and the former company building was renamed Yano Foods Co., Ltd. Second Factory. |

| May 2001 | Yano Foods Co., Ltd. Second Factory is reconstructed into a dedicated frozen Japanese confectionery factory and begins production of frozen foods (for commercial use). |

| In 2008 | Yano Foods Co., Ltd. Second Factory was converted to a factory dedicated to handmade o-hagi (rice cakes), and the main factory was converted to a frozen food factory. The main factory was converted to a frozen food factory. |

| June 2021 | Capital is increased to 15 million yen. |

| July 2023 | Obtained FSSC22000 Third-party certification. |

Our staff will contact you by e-mail.